Non-stick surfaces for demanding environments

Our belts help food and industrial manufacturers produce high quality products by minimizing wear and tear on their belts and maximizing productivity unlike standard grade products.

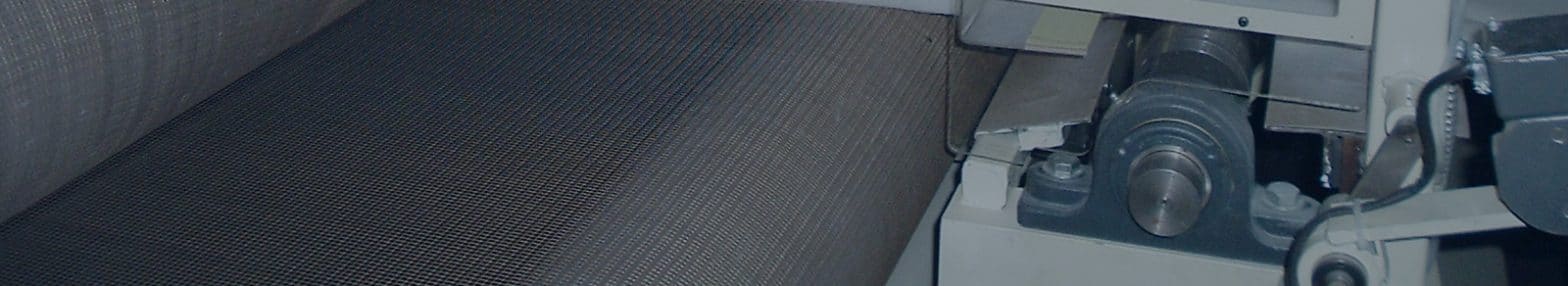

PROCESS AND CONVEYOR BELTING

Green Belting uses the highest quality fabrics and open mesh belting products for a wide range of custom and OEM applications. Fabric belts are hand crafted from PTFE and silicone coated glass fabrics and available in almost any length with widths up to 89” inches.

Choose from a variety of belting materials that have non-stick surfaces, are durable, resist chemical bonding, and that are resistant to high and low temperatures. Our belts are suitable for food handling and many other applications.

Belting for Demanding Environments

Looking for a conveyor belt best suited for your application? Contact our solution-driven staff at Green Belting who will be happy to help you.