THERMAL SPRAY AND MOLD RELEASE TAPES AND FABRICS TO REDUCE COSTS AND IMPROVE SCHEDULING

From protecting the molds of wind turbines, to creating that perfect weld on PVC Windows, our adhesive tapes, fabrics and heat resistant welding tapes will reduce your downtime, improve scheduling, and help you cut costs.

Wind Turbines

Production of wind blades in composite molds for clean energy.

PAINS:

- Time to line mold

- Defects in blade surface

- Cost of consumables

- Full range of products not available

- Time to line mold with release agent

GAINS:

- 30% more pulls

- Less defects resulting in less sanding

- Eliminating chemicals means less cleanup, less cost

- Less residue upon removal

- Variety of products for different applications

- Elimination/Reduction of release agents reducing time to line mold

RECOMMENDED PRODUCTS:

GR-6

GR-6 DXL-6S

DXL-6S 100-6S

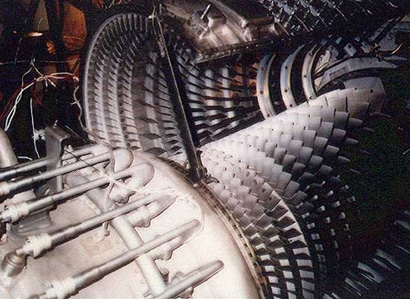

100-6SLand Turbines

Engine component repairs to help meet global energy demands.

PAINS:

- Strict standard operating practices that can’t be changed easily

- No traceability/lot code

- Damage of part during processing

- Too much preparation time prior to processing

- Scheduling issues due to poor adhesion

- High cost of masking

- Too much cleanup of adhesive residue

GAINS:

- Qualified suppliers list and standard practice manual

- Full traceability with DOM and lot number

- Stronger tapes that last longer

- Faster masking times

- Long term adhesion, improved scheduling

- Minimal adhesive cleanup post-process

RECOMMENDED PRODUCTS:

HVMT ORANGE

HVMT ORANGE 170-10S GREEN

170-10S GREEN 170-10S RED

170-10S RED 170-10S YL

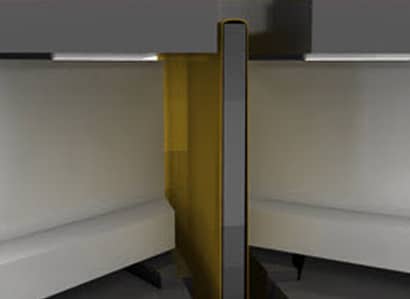

170-10S YLPVC Windows

Welding / Sealing of PVC to produce windows and sky lights.

PAINS:

- Long cycle times

- Too much downtime

- High cost of consumables

- Cleaning time of welding plates due to adhesive residue

GAINS:

- Higher temperature, wear resistant tape to reduce cycle times

- Long life adhesive withstands extremes without breaking down

- Use less tape for lower cost

- Minimal adhesive cleanup post-process

RECOMMENDED PRODUCTS:

GR-6

GR-6 DXL-6S

DXL-6S 100-6S

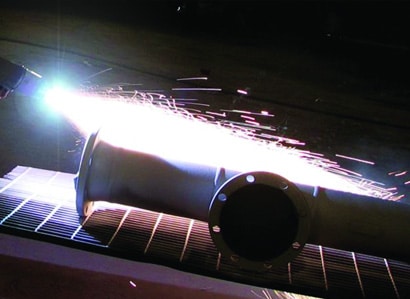

100-6SOil and Gas

Resurfacing of tooling related to gas and oil components.

PAINS:

- Too much preparation time prior to processing

- High cost of masking

- Waste due to short shelf life

- Too much cleanup of adhesive residue

- Damage of part during processing

- Scheduling issues due to poor adhesion

GAINS:

- Faster masking times

- Stronger tapes that last longer

- Longer shelf life than competition

- Minimal adhesive cleanup post-process

- Strong adhesive to protect part throughout surface preparation process

- Long lasting adhesion, improved scheduling

RECOMMENDED PRODUCTS:

HVMT ORANGE

HVMT ORANGE 170-10S GREEN

170-10S GREEN 170-10S RED

170-10S RED 170-10S YL

170-10S YLEnergy Sector Tapes and Technical Support from Green Belting

At Green Belting, we understand how important energy is to our day-to-day life. Our products can help manufacturers who repair engine components, produce wind turbine blades and manufacturing energy efficient PVC windows and other products to reduce waste and operational costs.

No matter your industry, Green Belting has a variety of thermal spray tapes, PTFE release films and fiberglass weld backing tape, and more to fit your needs.