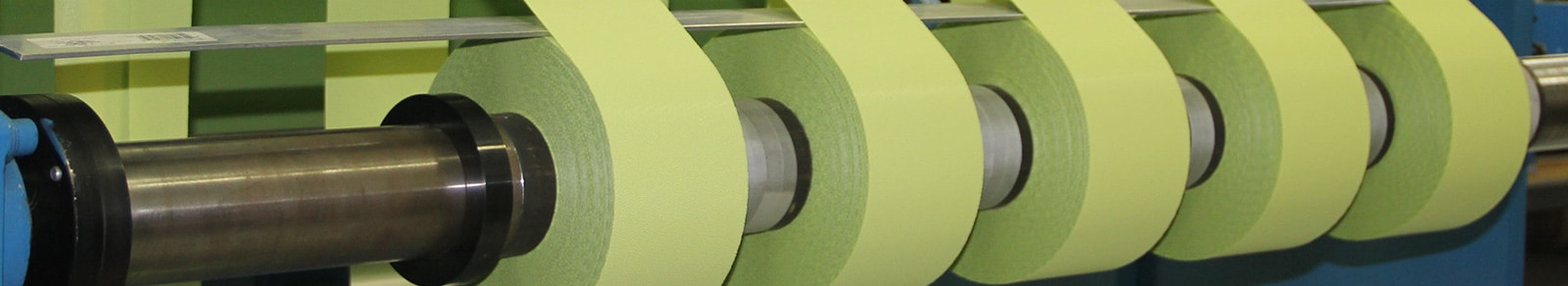

Figure 1 – Societal Threats1

From explosives and narcotics to pandemics, the societal threats to our safety and our health have become more intense and devastating. The ability for us to capture, analyze and react to these threats quickly and accurately is crucial to saving lives.

The fact is that the current failure rate in detecting explosives or ammunition is almost 80 percent2. Moreover, aviation is not the only ones that are currently struggling. The current pandemic is another example of how new threats crop up and have a disastrous impact around the globe as we struggle to contain them.

To respond to these threats within the ETD industry, there are three major challenges that need to be addressed when testing. These include:

- Human Error

- False Negative Results

- Swab Harvesting Efficiencies

Green Belting Industries manufactures ETD swabs are used to capture explosives in many of our airports and other market sectors around the world. Our proprietary process ensures low background noise to reduce false positives, lot-to-lot consistencies and increased harvesting efficiencies, which reduce the chance of false negatives.

Green Belting’s next generation ETD swabs focusses on improved sensitivity by increasing harvesting efficiencies and increasing sensitivity. How are we doing this?

In many cases, the amount of explosives collected is in the parts per million or parts per billion (PPB) range. Surface roughness, surface tension and thermal conductivity of the substrate or material used, plays an important role and can either improve or reduce harvesting efficiencies.

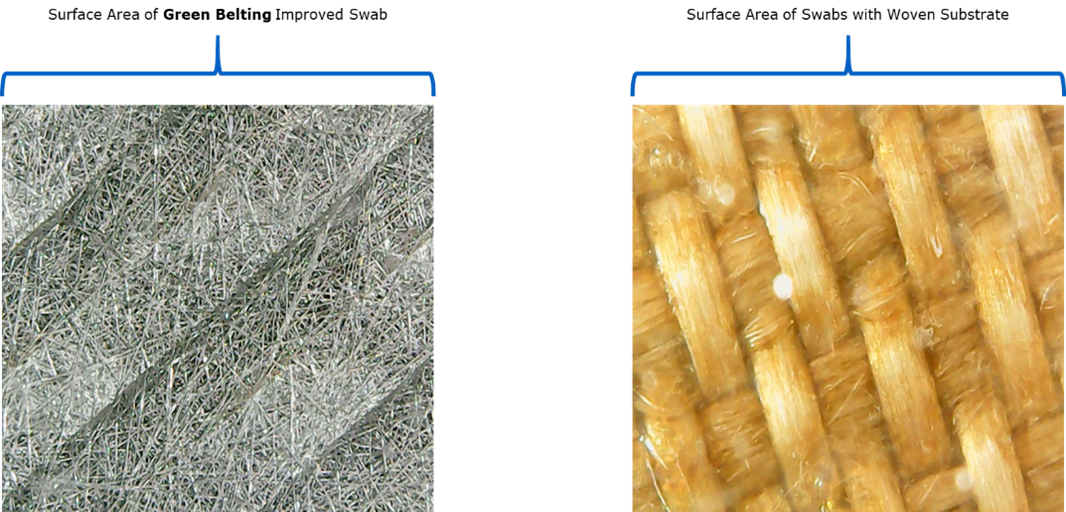

Improving the Surface Area

The traditional way of capturing explosives is using a woven polymer substrate. A more random surface structure in not only more flexible, but it also improves harvesting efficiencies.

Figure 2 – Swab Surface Area

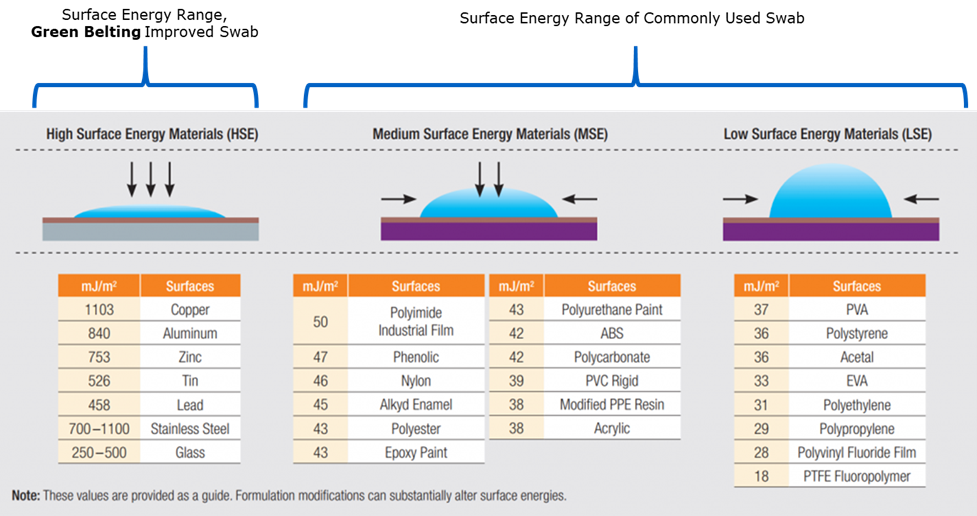

Increasing Surface Energy

Surface energy of the material used, directly impacts the adhesion properties and is directly proportional to the ability to collect and retain the chemical or explosive material to the swab. Increasing the surface area helps ensure positive results are achieved.

Figure 3 – Surface Energy3

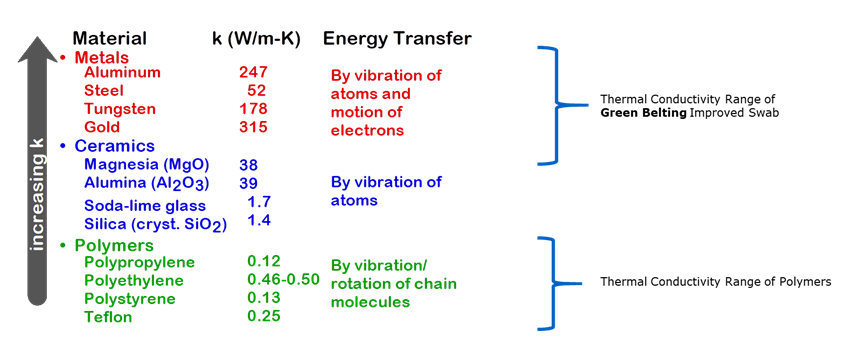

Increasing Thermal Conductivity

The ability to quickly transfer heat from the swab when analyzing with an Ion Mobility Spectrometer is critical as it helps ensure that the harvested explosives or chemicals are measured accurately. The “K” value identifies the ability to conduct heat. Current polymer substrates used in ETD swabs have a significantly lower “K” value than the improved ones from Green Belting.

Figure 4 – Thermal Conductivity Properties4

Technologies and security measures will need to be improved to stay one step ahead of today’s and future terrorists and pandemics. Green Belting Industries is committed to playing an important part in keeping us safe.

To find out more on how Green Belting has developed an ETD swab to help prevent explicit materials from travelling through our airports and public areas undetected, contact us.

- Image Source: “ Resources for Talking and Teaching About the School Shooting in Florida”, by Natalie Proulx and Katherine Schulten. https://www.nytimes.com/2018/02/15/learning/lesson-plans/resources-for-talking-and-teaching-about-the-school-shooting-in-florida.html

- Source: “Here’s How Bad the TSA IS Failing at Airport Security. It’s Time for Privatization.” by David Inserra and Ceara Casterline. https://www.heritage.org/transportation/commentary/heres-how-bad-the-tsa-failing-airport-security-its-time-privatization.

- Source: ” Surface Energy” by John Merchant. https://industrialcommunity.3m.com/blog/blog/

- Source: “Thermal Properties Heat Capacity Specific Heat Thermal Energy Mechanism Coefficient of Thermal Expansion Thermal Conductivity” By Jane Howard. https://slideplayer.com/slide/10352345/

RSS Feeds

RSS Feeds